Verisurf Universal Metrology Platform for the Manufacturing Enterprise

3D Measurement Platform

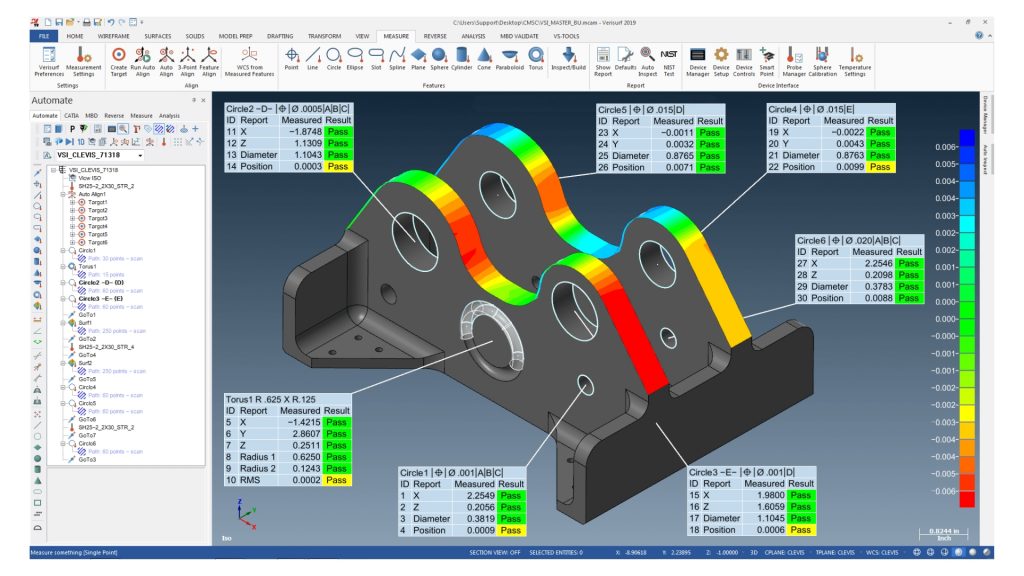

Verisurf software is a 3D measurement platform for manufacturing inspection, guided assembly and reverse engineering. Our open platform with enterprise interoperability empowers our customers to; open any CAD file or drawing, connect to any measuring device, align to any part or assembly, perform live or offline measurement tasks and quickly communicate results with colorful reports and database connectivity.

Powerful CAD Foundation

Verisurf CAD is the foundation of all our suites and includes; powerful NURBS surfacing and ParasolidTM solid modeling with model-associative GD&T. Our user experience is the most rewarding visualization experience in the metrology industry and is easy to learn because it adheres to the familiar Microsoft Ribbon Framework with Tabs, Groups, Panels and Galleries fully customizable to simplify and automate repeated processes.

Customization for Automation

The Verisurf SDK helps companies achieve Industry 4.0 automation objectives with a Application Programming Interface (API) that enables the creation of custom measurement applications with the power of Verisurf in the background. The API supports all popular scripting languages to create custom user interfaces to automate and simplify repeatable measurement driven processes.

Metrology Software Suites

CMM Programming & Inspection

Inspection & Analysis

3D Scanning & Reverse Engineering

- Quickly learned and retained by new users thanks to intuitive user interface with rich visual experience.

- Automate quality processes with repeatable measurement plans for any portable, manual or programable CMM.

- Teach programs or create them from CAD for measurable reduction in programming time and process execution.

- Run CMMs with Renishaw, Mitutoyo, Hexagon, Zeiss, or Pantec controllers, create reports and connect to quality databases.

- Connect to manual or portable CMMs and measure with probes and scanners from API, Creaform, FARO, Hexagon, Kreon, Leica, Nikon, and more.

- Inspect to drawings or CAD models with intelligent MBD and measure primitive features or complex profiles directly.

- Identify deviation and tolerance conditions between measured parts and nominal CAD in a premium user experience.

- Create meaningful quality reports in standard or custom formats and connect to popular FAI, SPC and QMS applications.

- Complete 3D SCAN-TO-CAD workflow quickly learned and retained by new users thanks to the intuitive user interface.

- Probe and scan directly with scanners and CMMs from API, Creaform, FARO, Hexagon, Kreon, Leica, Mitutoyo, Renishaw, WENZEL, and Zeiss.

- Extensive point cloud and mesh editing tools to automate 3D modeling including feature recognition and auto surfacing.

- Create NURBS surfaces and Parasolid solid models with model associative GD&T and export.

Metrology Technology

Learn more about dimensional metrology technology and applications.

The CMM is a measurement system designed for precision verification and documentation of manufactured parts and assemblies. They are programmed and/or controlled to take measurements of size, form, dimension, and relationships between features. Verification is based upon a comparison between the part and design definition established by engineering drawings and/or CAD definition.

First Article Inspection (FAI) is a manufacturing and quality assurance process to satisfy product specifications and quality requirements before full production begins. It typically involves a detailed examination of the first sample produced from a manufacturing run, known as the “first article.” This inspection is critical in scenarios such as:

Reference Point System (RPS) Alignment, also known as RPS Registration, is a principle for aligning 3D measurement inspection data to the 3D engineering design of a manufactured component or assembly. It brings the measurement data together with the computer-aided design (CAD) model of the product. (Technically, it could be used for parts designed from 2D drawings as well.)