Dynamic 9D Ladar

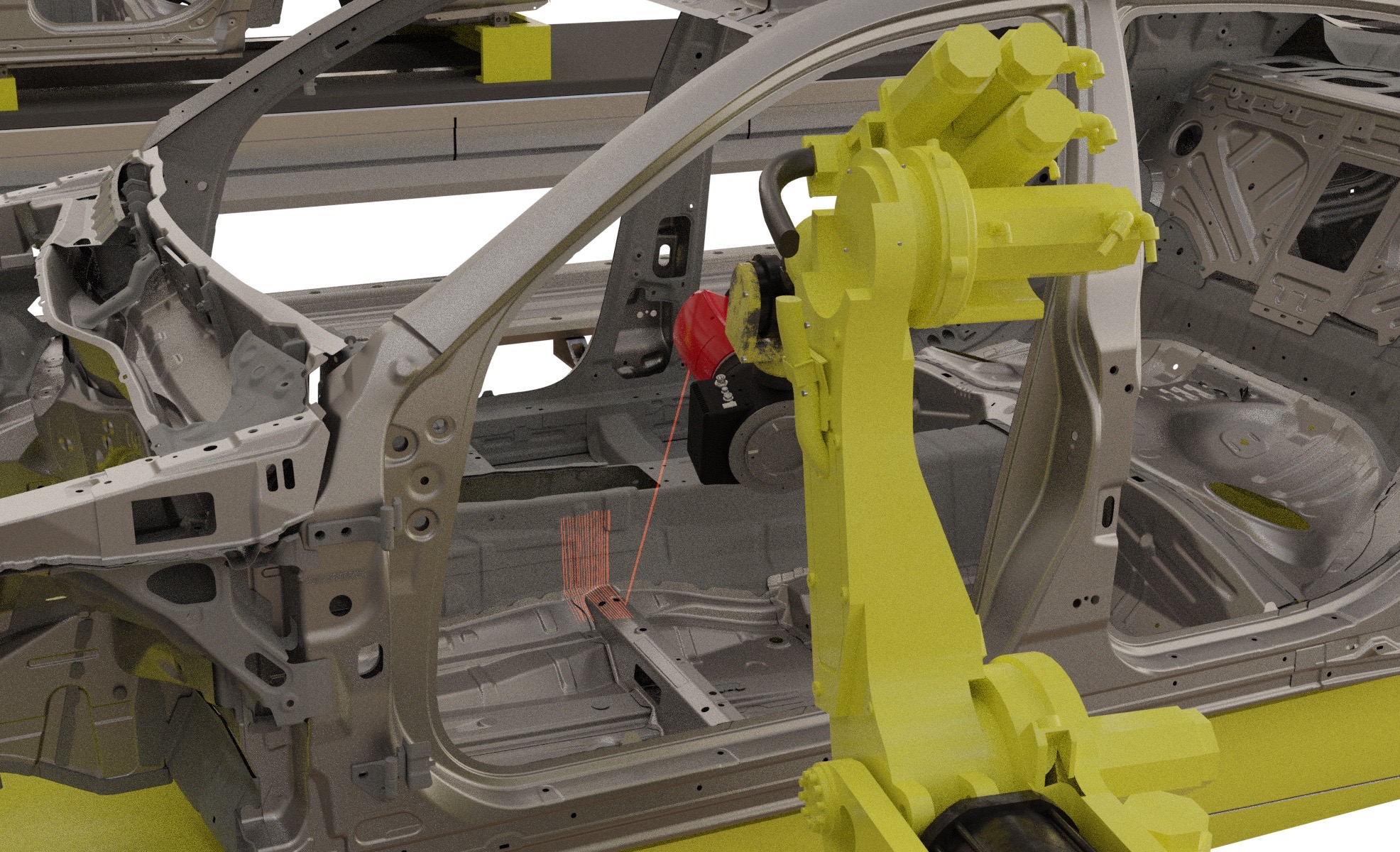

The 9D LADAR is a revolutionary non-contact measurement system that employs cutting-edge technology to acquire dimensional and surface geometry data at high speed and high precision.

The LADAR is designed for industries and professionals who require high-precision, non-contact measurements in real time. It is useful in quality control, inspection and manufacturing processes that need to acquire surface dimensional and geometric data quickly and accurately.

Optical CMM

CNC machine control

In-line dimensional measurement and control for the aeronautical, automotive, wind energy or similar industries

Flush and Gap

Component measurement

Equipment check

Reverse Engineering

Robotics

Dimensions X,Y,Z – I,J,K and R,G,B

API provides the tools with a standard 2-year warranty, underlining the confidence in its products.

The world’s fastest and most accurate interferometry-based non-contact measurement system

Designed to last over time

The robust and compact design minimizes errors.

Revolutionary technology

9D LADAR is an innovative technology, destined to revolutionize automated production measurement. The patent-pending LADAR is the fastest and most accurate interferometry-based non-contact measurement system incorporating OFCI (Optical Frequency Chirping Interferometry) technology.

Quick and efficient heat-up time

The centering of all heat sources allows for rapid heat distribution throughout the body of the instrument both during warm-up and for drastic changes in the temperature of the working environment, ensuring that the body of the tracker maintains a constant thermal balance, resulting Shorter warm-up time and superior measurements in stability.

Applications

9D LADAR acquires dimensional and geometric surface data intended for all manufacturing sectors such as: automotive, aerospace, naval, energy, transport, machine tools, robotics and construction.

Download the Data Sheet